true

- Overview

- Product Attributes

- Products & Accessories

- EIFU & Resources

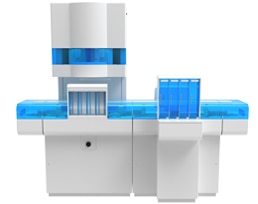

The BD Kiestra™ intelligent incubation and imaging system. Standardize incubation and imaging for digital interpretation by laboratory staff.

Powered by BD Synapsys™ microbiology informatics solution, the BD Kiestra™ ReadA intelligent incubation and imaging system provides closed door incubation and high throughput imaging, delivering accuracy through standardized digital image acquisition.

Enhance workflow

Provides accurate and consistent reading times with automated plate imaging, providing flexibility to laboratories to read images at different time-points per their operating protocols. This technology opens the possibility of new workflows across the incubation cycle.

Drive standardization

Helps enhance bacterial growth by standardizing incubation times and conditions in a controlled, closed-door environment. The BD Kiestra™ ReadA may increase bacterial growth by up to 31% compared to traditional microbiology 1

Improve operational efficiency

Improve operational efficiency by automating plate sorting and distribution. Plates are automatically delivered to the appropriate incubator to begin the incubation and imaging protocol.

Deliver accuracy

Capture images in a standardized manner to reduce variability, improve the consistency of results and see details invisible to the human eye.

Video Player is loading.

This is a modal window.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

BD Kiestra™ ReadA Overview Video

Flexible Connectivity

Available as part of a track-based BD Kiestra™ laboratory automation solution or as a standalone instrument, allowing flexible options based on your laboratory’s current workflow and size

Workflow management

BD Synapsys™ microbiology informatics solution provides a patient summary overview to assist culture interpretation by laboratory staff. Providing access to the right information anywhere, anytime with the BD Synapsys™ solution may help improve laboratory decision-making

Input stackers

Automate plate management with four input stackers enabling continuous loading of inoculated plates. Each stacker can be configured to a specific task, including a priority plate infeed to allow the handing of priority plates when needed

Output stackers

Automate plate management with 4 output stackers for user-configurable plate sorting including waste handling, follow-up work and offloading of plates for external incubation

Parallel plate processing

Four input stackers connect to the infeed track to automatically move plates in and out of the incubator

High throughput imaging

High speed camera that can image up to 300 plates per hour

Closed door incubation

Enables constant temperature and humidity at stable O2 or CO2 levels

Laminar air flow

Laminar air flow stabilizes conditions for every individual plate stored in the incubator minimizing the chance of plates drying out

Standardized incubation times

Plate protocol will direct incubation condition, incubation duration and image times.

Automated plate orientation

Plate labels are scanned prior to imaging to ensure full traceability and consistent orientation for improved reproducibility and productivity of result reporting

BD Kiestra™ Optis technology

High-quality camera with customized optics and plate orientation to normalize and standardize images made over time and minimize variation between instruments. With 22 images taken of each plate, optimal pixels are identified for ideal image representation

Three different light sources

Top, bottom and side light for optimal colony presentation on high resolution monitors

High quality plate imaging

25-megapixel camera with a telecentric lens

Literature

BD’s collection of literature on industry and on our offerings gives you information you can use to continue striving for excellence.

Learn more

References

- Klein et al. Significant increase in cultivation of Gardnerella vaginalis, Alloscardovia omnicolens, Actinotignum schallii, and Actinomyces spp. in urine samples with total laboratory automation. Eur J Clin Microbiol Infect Dis. 2018;37(7):1305–1311.

true